The juicy details

groov RIO’s main job in this system is to maintain pit temperature for the duration of the cookout. The firebox is still fed with wood, but Dave and his customer installed additional heater elements powered by a 30 A external generator to deliver more heat inside the cooking chamber. Dave wrote a program in Node-RED that allows groov RIO to cycle the heaters on and off based on low- and high-temperature limits until the preset cook time runs out.

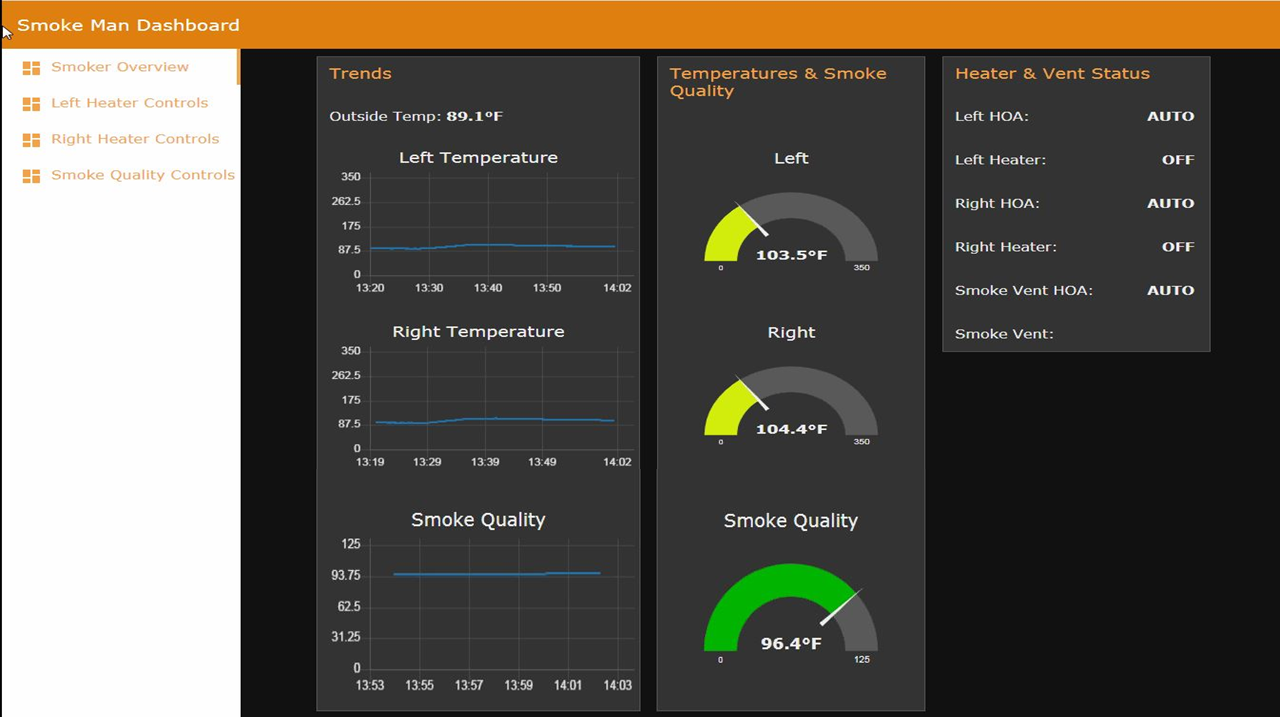

It was also important to Dave’s customer to be able to access the smoker controls on his phone, so he didn't have to drag a computer around. Dave connected a USB WiFi adapter to the groov RIO module, installed an industrial-grade access point in the trailer, and built a GUI in Node-RED.

The GUI accepts temperature setpoint and deadband values, which Node-RED uses to calculate appropriate high- and low-temperature limits for each of the two heating zones in the chamber.

“Being able to run [the GUI] with a browser is huge because it gives you a lot of flexibility,” says Dave. “You don't have to have someone's application software. Plus, it’s cross-platform and works on anyone's device. That's pretty huge, especially on these small applications, because people don't want to have to spend a bunch of money on developing and licensing an HMI.”

The GUI also allows the user to define a setpoint for smoke control that drives an actuator on the firebox outlet. The actuator can extend as much as 12", but for this application, Dave and his customer only needed a maximum 2.78" extension. Fortunately, since the rate of travel of a linear screw actuator is very consistent, Node-RED was able to control it very precisely with simple timing control.

With his groov RIO-based prototype, Dave’s customer can monitor the smoke process from the comfort of his living room using trend charts and warning indicators on the GUI. He can also switch into other control modes if he needs to get more hands-on. When the preset smoke time has run out, he gets a text message from Node-RED telling him it’s grub time!