Martins Electrical Service provides easy EaaS for OEM Shumaker Industries

groov RIO enables affordable equipment-as-a-service designs

The Challenge

Equipment-as-a-service (EaaS) involves renting out or providing access to equipment and collecting payment periodically, rather than selling the equipment outright. This payment model enables end users to pay for costly or infrequently used equipment as an ongoing operating expense, which can open new markets for machine builders.

Shumaker Industries is an OEM that builds automated truck wash systems, using a PLC to control position sensors, wash nozzles, and so on. Shumaker wanted to add a remote monitoring option for customers who were interested in a rent-to-own arrangement, but their PLC didn't have the ability to perform the database transactions they would need to monitor usage.

Martins Electrical Service (MES), the system integrator that Shumaker hired to design this new option, initially experimented with a proprietary remote monitoring system—wireless sensors that pumped data into a cloud database through a local IoT gateway. But the system could deliver updates only every 10 minutes, and that data was locked in the vendor’s private storage system.

Martins Electrical Service (MES), the system integrator that Shumaker hired to design this new option, initially experimented with a proprietary remote monitoring system—wireless sensors that pumped data into a cloud database through a local IoT gateway. But the system could deliver updates only every 10 minutes, and that data was locked in the vendor’s private storage system.

"Then we got an email from [Opto 22] about groov RIO,” says Leslie Martin, an automation technician at MES, “and I said, 'That is exactly what we want!'"

The Solution

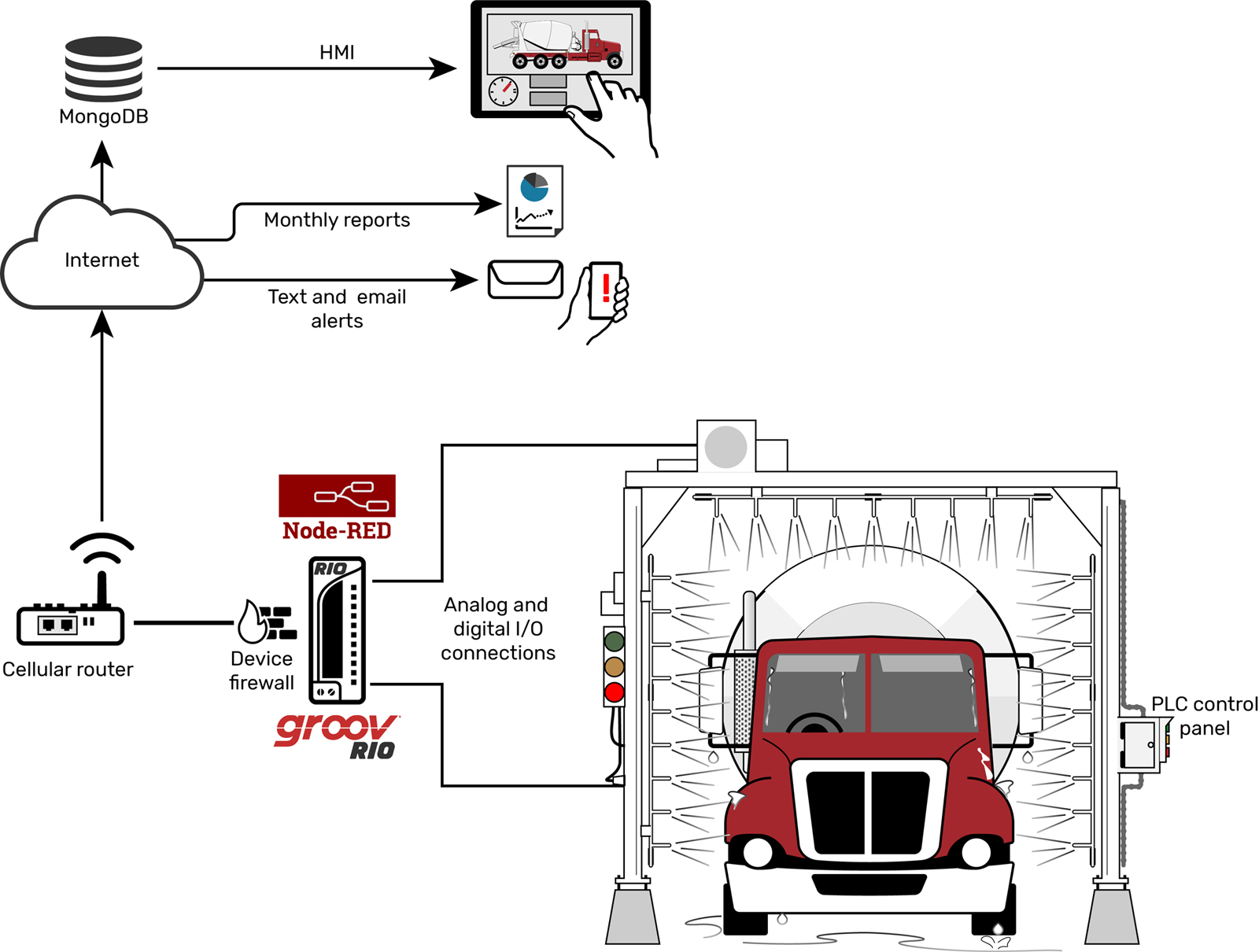

MES took a new approach. Rather than installing additional sensors, they used groov RIO's 10 software-configurable I/O channels to capture existing sensor data in parallel with the wash system’s PLC. Then, using Node-RED—IBM’s open source IoT platform embedded in groov RIO—they organized that I/O data into timestamped sets associated with a vehicle number. Finally, they connected a 4G cellular router to groov RIO and pushed those data structures from Node-RED directly to cloud-hosted storage, which they rented from MongoDB.

MES’s monitoring system uses groov RIO to grab existing I/O signals, send them into cloud storage, and generate useful alerts and reports

This approach allowed them to deliver a scalable monitoring system without worrying about vendor lock-in or IT infrastructure maintenance. And by simply grabbing existing I/O signals, they avoided the need to communicate with or modify Shumaker’s existing PLC controls.