Need to bring field device data into on-premises or cloud applications?

Are you:

- Monitoring remote assets?

- Acquiring data for analysis or regulatory purposes?

- Controlling standalone equipment and devices?

- Creating process visualization for operators and supervisors?

Now you can get the data you need where you need it, easily and affordably, with groov RIO.

No PLCs, PCs, or middleware required.

What is groov RIO?

groov RIO is an independent, intelligent Ethernet-based edge I/O module designed for IIoT and automation applications. It solves two main problems with most remote I/O today:

- First, specifying all the required components (rack, power supply, bus coupler, module types, and more) is time-consuming, difficult, and requires special skills.

- Second, communicating data among field devices, control systems, business applications, and cloud services is complex and costly, requiring PLCs, custom programming, and other expensive middleware.

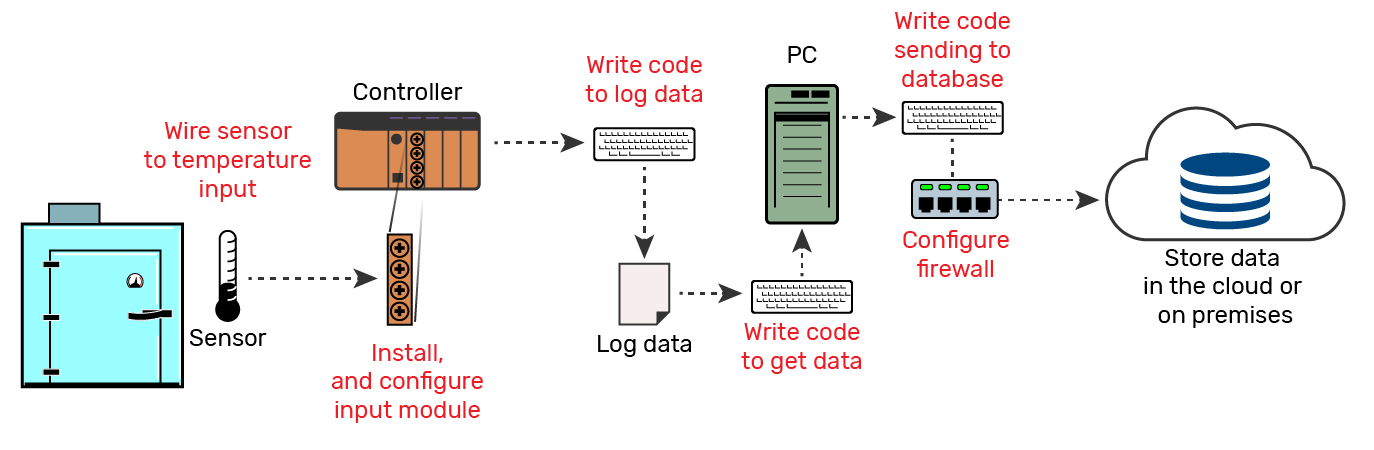

Logging temperature to a database is too complex:

groov RIO revolutionizes remote I/O by solving both problems:

- One part number. A single device provides built-in I/O, an intelligent I/O processor, power over Ethernet, two mounting options with no rack or chassis, and software—in a compact industrial housing.

- Built-in processing and communication. Embedded web-based configuration, flow logic software, efficient data communication methods like MQTT, and multiple operations technology (OT) and information technology (IT) protocols simplify any IIoT or automation application.

What's more, you can even run a control program on

groov RIO, right there in your remote I/O at the edge. The optional CODESYS license for

groov RIO (

GROOV-LIC-CRE-RIO) lets you build a control application in any IEC 61131-3 compliant language. It's ideal for OEMs with limited space and standalone equipment.

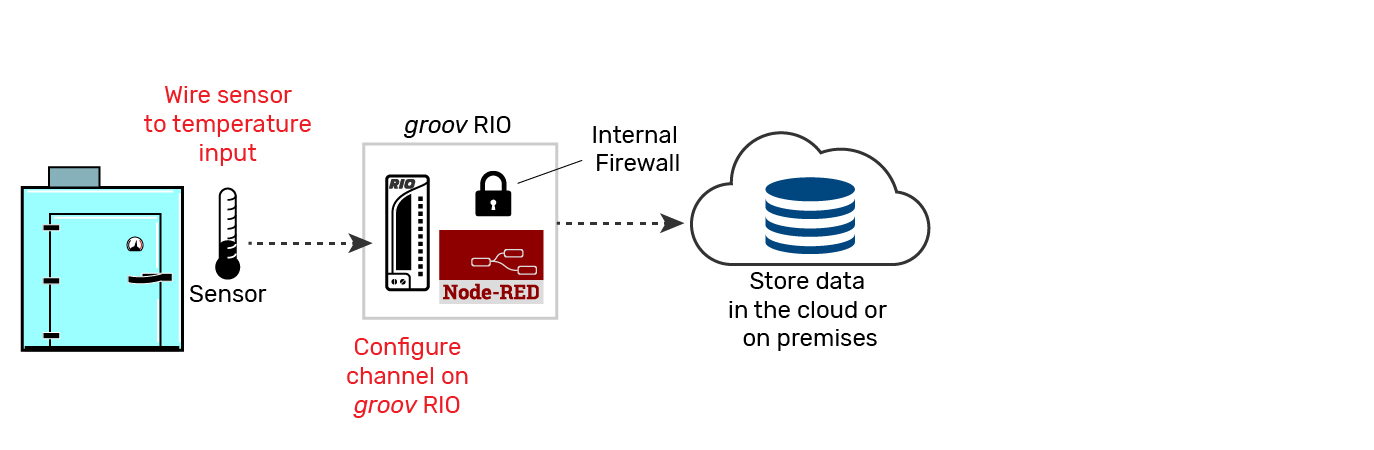

Logging temperature to a database is simplified with groov RIO:

groov RIO is Edge I/O

These features make groov RIO an advanced kind of I/O product—edge I/O—that reduces IIoT complexity. Edge I/O and edge computing both offer traditional industrial functions at the edge of your network, which is the source of sensor and equipment data. But they also add the ability to easily connect to data consumers on a computer network or over the internet. Learn more about edge I/O.

Edge computing products like Opto 22’s

groov EPIC edge programmable industrial controller are proving to be a scalable, efficient model for adding IoT connectivity to industrial applications. Now

groov RIO brings that same kind of connectivity to the I/O level, without the need for a controller (or providing control in itself).

groov RIO simplifies the current complexity of IIoT applications.

IIoT projects are too complex

With today’s connectivity and technical capabilities, it seems like simple IIoT applications should be simple to achieve.

We can do IIoT projects now, but without edge I/O, it’s too hard:

- First, you—or someone you hire—needs to specify and procure all the components of an I/O or PLC system that will work with the field signals you have.

- Then you install an enclosure for the PLC and I/O, assemble them, and supply power.

- Next, you install the sensors and actuators and connect them to channels on I/O modules mounted on the PLC rack.

- Then you use the vendor’s proprietary software to program the PLC, configure the channels for the correct signal types, and acquire and log the I/O data.

- Next, you need a PC with software that can read the PLC’s memory and translate the logged data into a format understood by the destination software, service, or system you’re sending the data to.

- Finally, some software needs to log into the destination and post the data. And if the destination isn’t on premises, or in the cloud somewhere that’s accessible, good luck!

groov RIO gets the data now. No PLC, no PC, no middleware

Edge I/O avoids complexity and the time and money costs that go with it. With

groov RIO, you can:

- Choose the groov RIO model for your application: universal I/O with thousands of possible field I/O combinations, with or without Ignition Edge from Inductive Automation, or the groov RIO energy monitoring module with 64 channels of power and energy data.

- Place the unit almost anywhere for remote I/O and data communications. It’s UL Hazardous Locations approved and ATEX compliant, DIN-rail or panel mounted, and may not even need an enclosure.

- Connect to proprietary machines or processes without disturbing them, paralleling machine I/O to gain the data you need to use elsewhere.

- Supply power to groov RIO and field I/O through the ETH1 network interface using Power over Ethernet. Or connect a 10-32 VDC power supply.

- Connect your own Wi-Fi adapter, USB memory stick for local data storage (up to 32 GB), or USB-to-serial adapter.

- Enable MQTT on RIO to securely and efficiently send data—as Sparkplug-B or string payloads—to MQTT brokers on premises or in the cloud. Other devices and software can subscribe to the data as needed.

- Access I/O values, Scratch Pad areas, and PID values on RIO with its onboard OPC UA server (groov RIO firmware 3.4 and higher).

- Create simple data flows with built-in Node-RED to send data to cloud services, databases, other I/O channels, and APIs through pre-built nodes.

- Even add real-time control with a CODESYS license (GROOV-LIC-CRE-RIO), so you can run control applications you build in any IEC 61131-3 compliant language.

- Manage security, including device firewall, security certificates, and user authentication and permissions via LDAP centralized user account management (LDAP requires groov RIO firmware 3.0 or higher).

Get the data you need, where you need it, now.

Get groov RIO.

See how groov RIO fits in your system architecture.

See groov RIO videos.

Learn about power and energy monitoring with groov RIO.

Download the groov RIO Univeral I/O product brochure or the groov RIO Energy Monitoring Unit brochure.

Get groov RIO now!

| Part Number |

|

Description |

| GRV-R7-MM1001-10 |

- |

groov RIO MM1 universal edge I/O, 8 multifunction signals, 2 Form C relays, no Ignition |

| GRV-R7-MM2001-10 |

- |

groov RIO MM2 universal edge I/O, 8 multifunction signals, 2 Form C relays, expanded memory, Ignition Edge 8 pre-installed |

| GRV-R7-I1VAPM-3 |

- |

groov RIO EMU, energy monitoring edge I/O module, 64 channels of power and energy data |