The system

For ACE, Microclimates recommended a combination of existing and new third-party sensors, connected to Opto 22 groov RIO remote I/O modules, either by direct wiring or via Modbus through a serial-to-USB converter connected to the RIO’s USB port. Sonic sensors on a 4-20 mA circuit, for example, are wired directly into the groov RIO software-configurable I/O channels. The industrially hardened groov RIO, in addition to remote I/O connections, offers features designed for IIoT applications, including cybersecurity, power over Ethernet (PoE), several OT and IT protocols, and the ability to run programs loaded to its Linux OS via secure shell access (SSH).

Using SSH, Microclimates installs their software on the groov RIOs along with development tools including Prometheus for a database, Grafana for visualization and dashboarding, and Loki for logging. This software all runs at the edge on multiple RIOs to handle climate sensing, liquid sensing and electroconductivity (EC), and valve control.

Loren West, Microclimates Software Architect, says, “The RIOs are all PoE powered. They’re connected to the sensors that measure pH, dissolved oxygen, temperatures, water level, humidity, and so on.” In addition, power sensors monitor all power.

Brian Cook, Lethbridge Research Technologist, worked closely with Loren to design and install the system. “The level of service was the most decisive factor in choosing Microclimates,” says Brian. “Also the ease of installation. We just plugged the sensors and RIOs in and let them go. We had no issues. We were up and running within a day or so, unlike other systems. And they’re reliable.”

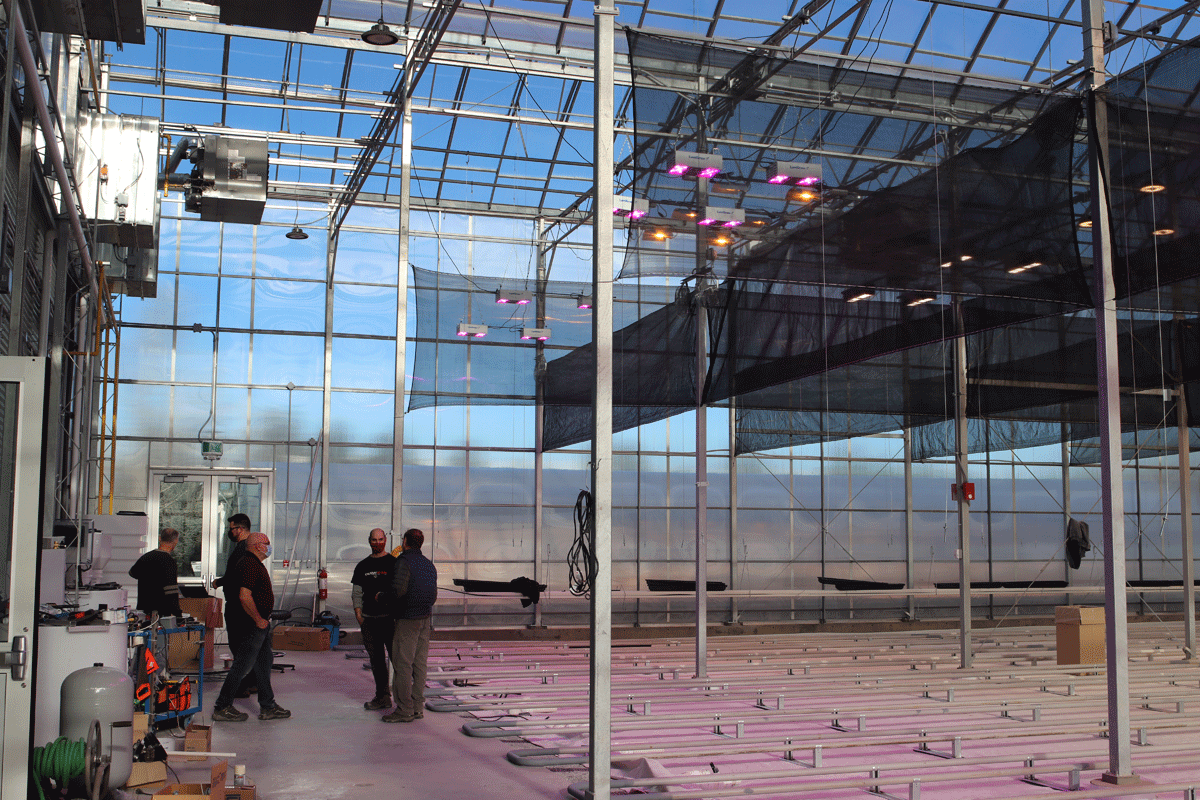

The Aquaculture Centre of Excellence greenhouse under construction

The ability to configure I/O in software was also an important feature for Brian. One sensor runs on resistance, for example, and he could configure the channels easily using just a web browser.

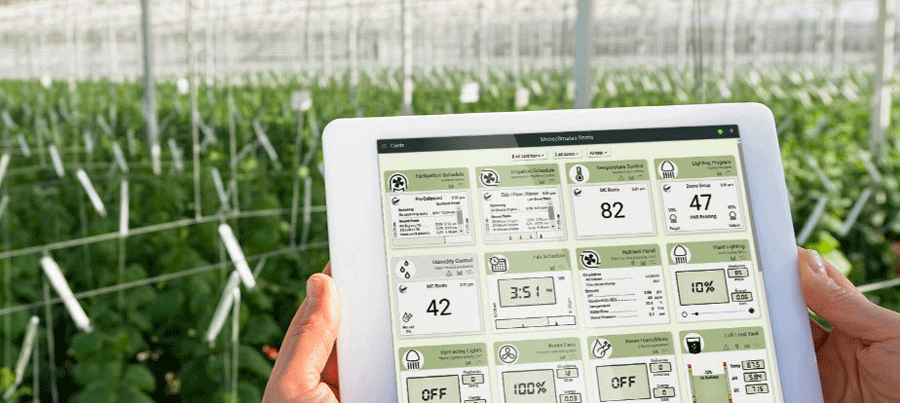

The Microclimates software collects data, shows trends, and makes decisions, for example to control valves. At present, researchers do not require historical data. It will become important in future studies, but currently they use real-time data to determine how things are working, so they can change settings for research purposes.

Aquaponics and more

In addition to ongoing research on aquaponics, the Centre is now working toward no-waste agriculture. Their new bioreactor system, also monitored and controlled by Microclimates and Opto 22 groov RIOs, employs aerobic reactors to take solid organic waste—fish, pig, and chicken manure, for example—and convert it to fertilizer.

“The remarkable thing about this research is that it’s different from digesters,” notes Nick. “It has 100% recovery and is a much faster process than composting or other methods.” Brian says the main advantage to the bioreactor system to him as an operator is that there’s absolutely no smell.

The livestock industry offers huge applications for the bioreactor system, and it could even be used in the future for human waste. ACE and Microclimates intend to develop a package for the livestock application including controls.

In sum, aquaponics, hydroponics, and two bioreactor circuits are the Centre’s four main areas. They have four separate water sources and can deliver any one to any section at any time. Usually two are run at a time, but they may run all four simultaneously and can control all four circuits at once. The groov RIOs can operate totally independently of each other but can also talk when they need to.

In addition, the greenhouse is divided into 18 cells. “This allows us to conduct six experiments with three repeats or three experiments with six repeats, or several other combinations,” says Brian, with all experiments controlled by the Microclimates system. The researchers find daily graphs extremely useful for making small adjustments on a daily basis, for example increasing watering time to improve efficiency and plant health. Graphs also show any power failures and their results.

Current plans also call for a light-intensity study with LEDs. Since Alberta is fairly far north and daylight is limited, especially in the winter, research on adding daylight is valuable for the region.

Cybersecurity

The college is extremely wary of any outside system coming into their network. Lethbridge’s IT department spent three days going through cybersecurity requirements with Loren and then approved the Microclimates system and groov RIO modules.

“We use the standard RIO network settings with default DHCP/DNS assignments from the college’s IT network. It’s already set up and no changes are needed to network settings,” says Loren. “A lot of companies use systems like this the old-fashioned way—having to set static IPs, for example—but with RIO we don’t need to.”